When it comes to optimizing warehouse space and improving efficiency, pallet racking systems are a popular choice for businesses of all sizes. Selective pallet racks are an essential component of any warehouse that deals with bulk materials, as they allow for easy access to individual pallets without disturbing the rest of the inventory. However, before investing in this type of storage system, it’s important to understand what size is required for your specific needs.

In this article, we’ll explore the various dimensions and configurations available in selective pallet racks. We’ll discuss how factors like ceiling height, floor space, and inventory volume can impact your decision-making process when selecting a rack size.

Defining Selective Pallet Racks

Selective pallet racks are the most commonly used type of warehouse racking. It is a term used to describe a rack that is designed for storing palletized goods and materials. Selective racks are generally made up of vertical uprights, horizontal load beams, and wire decking or plywood shelving.

The size of selective pallet racks can vary based on the requirements of the warehouse or storage facility. The height, width, and depth dimensions can be adjusted to suit the specific needs of the space that it will be installed in. The height typically ranges from 8 feet to over 30 feet tall, while the width can range from 6 to 12 feet wide.

Overall, selective pallet racking is versatile and customizable, making it an excellent option for warehouses with varying storage needs. Its design allows for easy access to all stored items which makes it ideal for inventory management systems where quick retrieval time is required.

Standard Sizes: Common Dimensions

Selective pallet racks are one of the most common types of warehouse storage systems used in industries worldwide. These racking systems are designed to store and organize pallets containing industrial goods, raw materials, or finished products. The standard size of a selective pallet rack is 10 feet high and 42 inches wide. Each upright frame consists of two columns that can support horizontal beams at different levels.

The standard size of the horizontal beams ranges from 8 feet to 12 feet long, depending on the load capacity required by the user. Additionally, each beam has a width range between 2-3 inches and can hold varying weight capacities based on its thickness. Selective pallet racks come with either bolted or welded frames that offer greater structural stability and durability to withstand heavy loads.

Overall, these standardized dimensions allow for easier installation and customization while ensuring optimal safety during use, making selective pallet racks an ideal choice for businesses seeking efficient storage solutions within their warehouses.

Customizable Options: Tailored to Your Needs

When it comes to warehouse storage, selective pallet racks are a popular choice due to their versatility and accessibility. But what size is a selective pallet rack? The truth is, there isn’t one standard size for this type of racking system as it can be customized to fit the specific needs of your warehouse.

Customizable options allow you to tailor the height, width, depth, and even weight capacity of your selective pallet rack to best suit your inventory and space constraints. For example, if you need more vertical storage space but have limited floor space, you can opt for taller uprights with narrower beams. On the other hand, if you have heavy or bulky items that require a sturdier shelf than most standard racking systems offer, you can specify thicker gauge steel or additional bracing.

By choosing customizable options for your selective pallet rack, you not only ensure that it fits perfectly in your warehouse but also maximizes its efficiency by accommodating your unique inventory and handling processes. So whether you’re storing large quantities of lightweight products or an assortment of heavy items with varying dimensions, there’s a custom solution out there for you.

Load Capacities: Essential Considerations

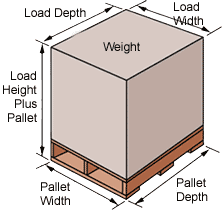

When it comes to pallet racking, one of the most important considerations is load capacity. Load capacities refer to the maximum weight a rack can hold without risking structural failure or collapse. It’s essential to consider load capacities when designing a pallet racking system because exceeding them could result in serious safety hazards and equipment damage.

There are several factors that affect load capacity, including the dimensions of the rack itself, the type of material used in construction, and the number and spacing of support beams. In addition to these factors, it’s necessary to consider how much weight will be stored on each shelf or level within the racking system.

To ensure safe and efficient operation of your pallet racks, it’s crucial to consult with experienced professionals who can help you determine appropriate load capacities based on your unique needs and requirements. By working with experts in the field, you can rest assured that your pallet racking system will meet all safety standards while providing optimal storage capacity for your inventory.

Space Requirements: Maximizing Storage Efficiency

Selective pallet racks are one of the most common types of storage systems used in warehouses and distribution centers. They are designed to provide easy access to individual pallets, making them ideal for facilities that require frequent inventory turnover. The size of a selective pallet rack can vary depending on the specific needs of the facility.

Typically, selective pallet racks are between 8 and 12 feet tall and 36 to 48 inches deep. The width can range from 6 to 10 feet, with each section able to hold up to two standard-sized pallets side by side. The distance between each level or beam can be adjusted based on the dimensions of the stored items.

To maximize storage efficiency with selective pallet racks, it is important to consider factors such as aisle width and product rotation frequency. Narrower aisles allow for more racking within a given space but may require specialized equipment for handling products. Additionally, proper labeling and organization can help ensure that items are easily accessible when needed while also reducing the risk of damage during retrieval.

Installation and Maintenance: Proper Handling

When it comes to installation and maintenance of selective pallet racks, proper handling is crucial. Selective pallet racks are available in various sizes depending on the needs and requirements of the user. The standard size for a selective pallet rack upright frame is 3 inches wide by 1-5/8 inches deep, while the standard beam length ranges from 96 inches to 144 inches.

During installation, it is vital to handle the components with care to avoid any damage that could compromise safety. This includes following manufacturer instructions and guidelines for assembly, ensuring that bolts and nuts are tightened securely, and checking for any signs of wear or damage before use.

Maintenance involves regular inspections of the system to identify any defects or potential hazards. It also includes routine cleaning and lubrication of moving parts such as beams and braces. By adhering to proper handling practices during installation and maintenance, users can ensure safe operation of their selective pallet rack system for years to come.