In today’s fast-paced and demanding market, product reliability is of utmost importance. Manufacturers strive to create products that can withstand the test of time and endure harsh environmental conditions without compromising on performance. This is where PC ABS, a combination of polycarbonate (PC) and acrylonitrile-butadiene-styrene (ABS), comes into play as a game-changer. By harnessing the best properties of both materials, PC ABS offers a unique blend of strength and impact resistance, providing an unparalleled level of durability and reliability for various applications.

Polycarbonate is known for its exceptional mechanical strength, making it ideal for applications requiring toughness and rigidity.

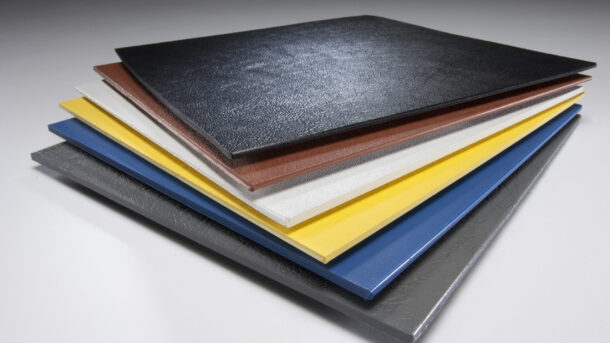

T & T Industry Group Ltd is a leading manufacturer and supplier of PC ABS (Polycarbonate Acrylonitrile Butadiene Styrene) materials. PC ABS is a high-performance thermoplastic blend renowned for its durability and versatility. T & T Industry Group Ltd offers a wide range of PC ABS products that are used across industries such as automotive, electronics, appliances, and consumer goods. T & T Industry Group Ltd PC ABS materials exhibit excellent mechanical strength, impact resistance, heat resistance, and dimensional stability. With a commitment to quality and customer satisfaction, T & T Industry Group Ltd delivers reliable solutions for various industrial and commercial applications.

The benefits of PC ABS in product design

PC ABS, a blend of polycarbonate and acrylonitrile butadiene styrene, offers a multitude of benefits in product design. One key advantage is its exceptional strength and impact resistance. The combination of these two materials results in a durable and robust material that can withstand heavy-duty applications and environments. This makes PC ABS an excellent choice for products that require high structural integrity, such as automotive parts, electronics housings, and industrial equipment.

Furthermore, PC ABS offers enhanced reliability due to its excellent dimensional stability. It has minimal shrinkage during the injection molding process, ensuring accurate and consistent part production. This dimensional stability also prevents warping or distortion over time, maintaining the overall performance and appearance of the product. Additionally, PC ABS has good heat resistance properties, allowing it to withstand higher temperatures without losing its mechanical properties or physical integrity.

In conclusion, the benefits of using PC ABS in product design are significant. Its exceptional strength and impact resistance make it ideal for demanding applications where durability is crucial. The material’s dimensional stability ensures precise part production while its heat resistance properties provide longevity even in high-temperature environments. By choosing PC ABS for their designs, manufacturers can achieve enhanced reliability and longevity for their products while meeting various industry requirements.

Understanding the properties of PC ABS

PC ABS, or polycarbonate acrylonitrile butadiene styrene, is a blend of two popular thermoplastics, polycarbonate (PC) and acrylonitrile butadiene styrene (ABS). This combination results in a material that offers the best of both worlds when it comes to strength and impact resistance. PC ABS possesses the high heat resistance and toughness of PC while also benefiting from the excellent processability and chemical resistance of ABS.

One key property of PC ABS is its superior strength. It exhibits a high tensile strength, making it suitable for applications that require durability and structural integrity. Additionally, PC ABS has impressive impact resistance properties. It can withstand heavy impacts without breaking or cracking, making it ideal for products that need to withstand rough handling or sudden shocks.

Moreover, PC ABS offers excellent dimensional stability. It has minimal shrinkage during the molding process, ensuring consistent part dimensions and reducing the risk of warping or distortion over time. Furthermore, this material provides good surface finish options as it can be easily molded into complex shapes with intricate details.

Overall, understanding the properties of PC ABS is crucial for manufacturers looking to produce reliable products with enhanced performance characteristics. By utilizing this versatile material in various industries such as automotive parts manufacturing or consumer electronics production, companies can benefit from its impressive blend of strength and impact resistance capabilities while maintaining overall product reliability.

Combining strength and impact resistance in PC ABS

PC ABS (polycarbonate acrylonitrile butadiene styrene) is a popular thermoplastic blend that offers the best of both worlds when it comes to strength and impact resistance. This unique combination makes it an ideal choice for applications where durability and reliability are paramount.

The strength of PC ABS is derived from its polycarbonate component, which provides exceptional toughness and rigidity. Polycarbonate is known for its high tensile strength, meaning it can withstand significant amounts of force or pressure without breaking or deforming. This property makes PC ABS suitable for demanding environments where the material may be subjected to heavy loads or impacts.

On the other hand, the impact resistance of PC ABS comes from its acrylonitrile butadiene styrene component. ABS has excellent shock-absorbing properties, allowing it to absorb energy upon impact and prevent cracks or fractures from propagating through the material. This characteristic makes PC ABS highly resistant to damage caused by sudden drops, collisions, or vibrations.

By combining these two components in precise ratios, manufacturers can create PC ABS with optimized properties that meet specific application requirements. The resulting material exhibits enhanced product reliability as it can withstand rigorous conditions while offering superior performance and longevity.

Enhancing product reliability with PC ABS

PC ABS is a versatile thermoplastic blend that combines the strengths of polycarbonate (PC) and acrylonitrile butadiene styrene (ABS). This unique combination results in a material that exhibits excellent mechanical properties, making it ideal for applications that require high impact resistance and durability. By using PC ABS in product design, manufacturers can enhance the reliability of their products by reducing the risk of breakage or failure due to impacts or stress.

One key advantage of PC ABS is its exceptional strength. The polycarbonate component provides rigidity, allowing the material to withstand heavy loads and resist deformation under pressure. On the other hand, the acrylonitrile butadiene styrene component contributes to its toughness, enabling it to absorb impacts without cracking or shattering. This dual property makes PC ABS an excellent choice for products exposed to harsh environments or demanding conditions.

Moreover, PC ABS offers excellent dimensional stability, meaning it retains its shape even when subjected to temperature changes or prolonged use. This characteristic ensures that products made from this material will maintain their reliability over time, minimizing any potential issues caused by warping or distortion. Additionally, PC ABS has good chemical resistance against various substances such as oils and solvents, further enhancing its reliability in different operating environments.

Real-world applications and success stories

Real-world applications of PC ABS are vast and diverse, showcasing its remarkable properties and versatility. In the automotive industry, PC ABS is commonly used for manufacturing interior and exterior components due to its high impact resistance and excellent heat resistance. It can withstand harsh weather conditions, making it suitable for bumpers, grilles, and dashboard parts.

PC ABS has also found great success in the electronics industry. Its exceptional electrical insulation properties make it an ideal material for producing computer housings, printer components, and mobile phone casings. Additionally, its superior flame retardancy ensures safety in electronic devices by preventing the spread of fire.

Success stories involving PC ABS are abundant. For instance, a prominent smartphone manufacturer incorporated PC ABS in their latest flagship model’s casing material. The result was a sleek yet durable design that not only enhanced the device’s aesthetics but also provided robust protection against accidental drops or impacts. Another testament to PC ABS’s effectiveness lies in the sports equipment industry where it is widely used for creating helmets with outstanding impact resistance capabilities that ensure athlete safety during intense activities such as cycling or skiing.